About Machinable Glass Ceramic(MGC)

Machinable Glass Ceramic (also known as “Machinable ceramic”) is a polycrystalline composite material, white in its entire body. It is a glass ceramic material with synthetic mica crystallites as the main crystal phase. Machinable ceramic have high mechanical strength, excellent dielectric properties and thermal properties, and good chemical stability.

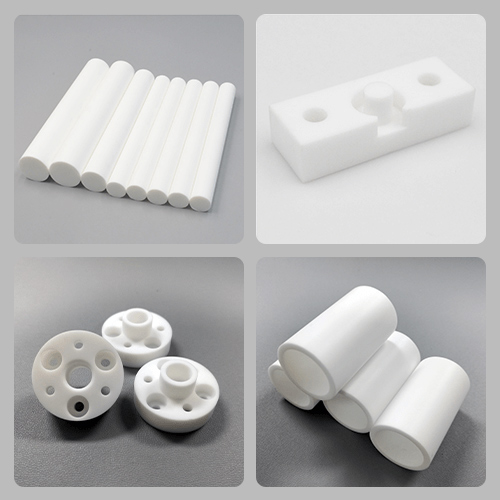

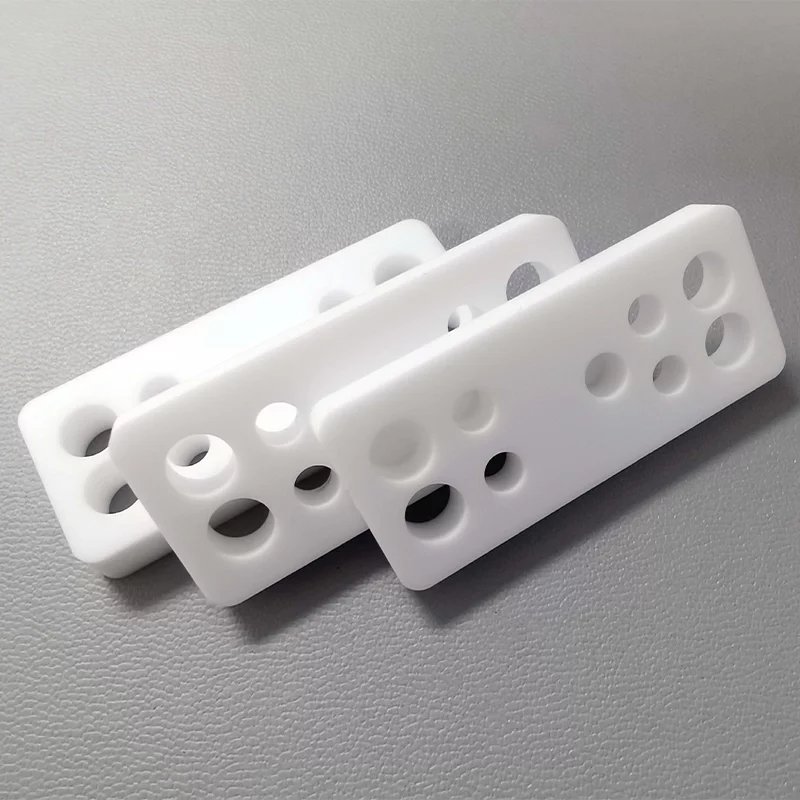

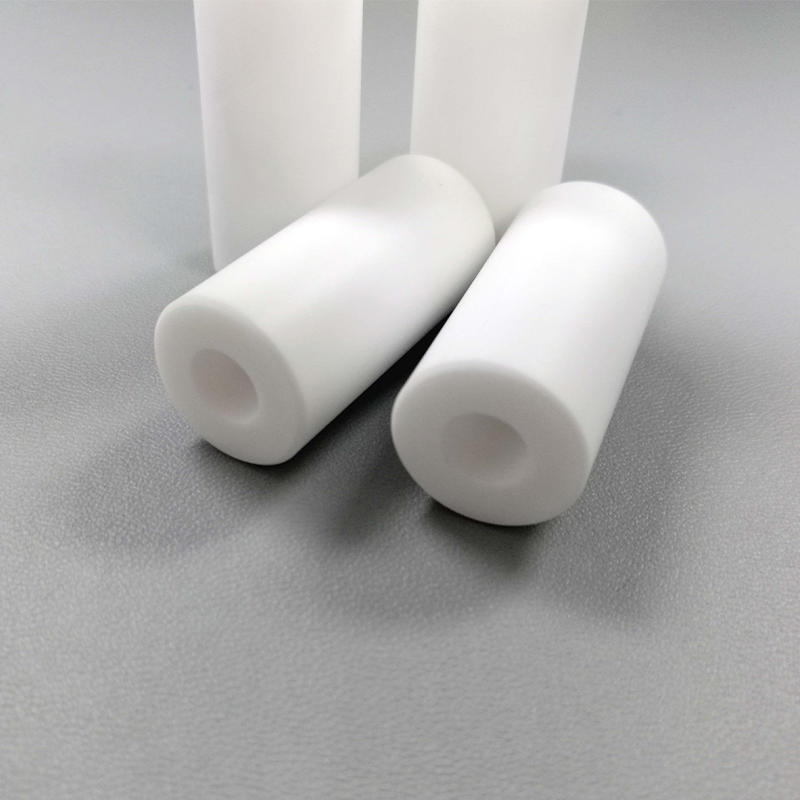

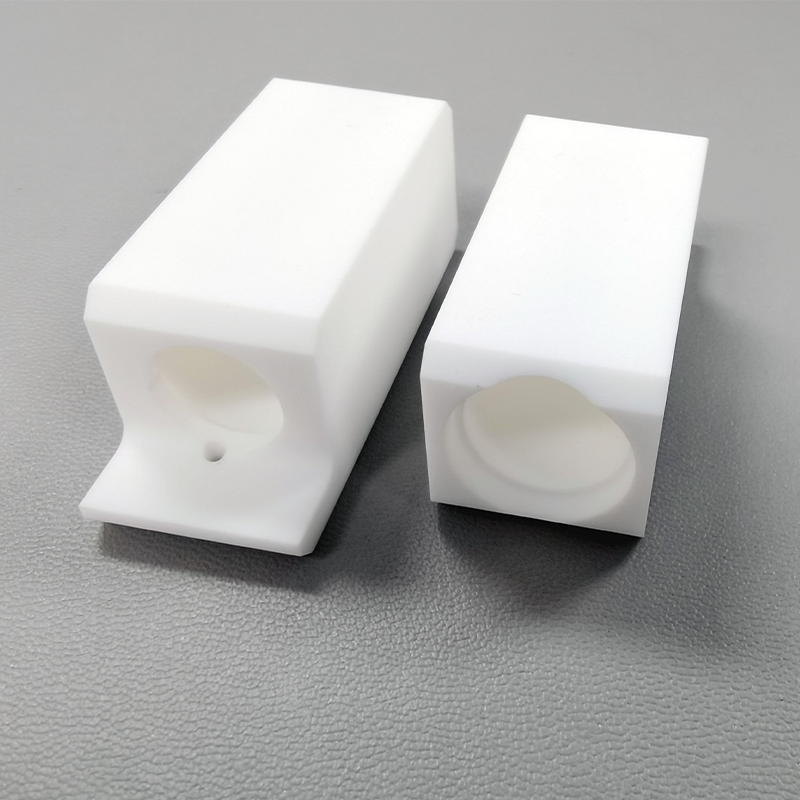

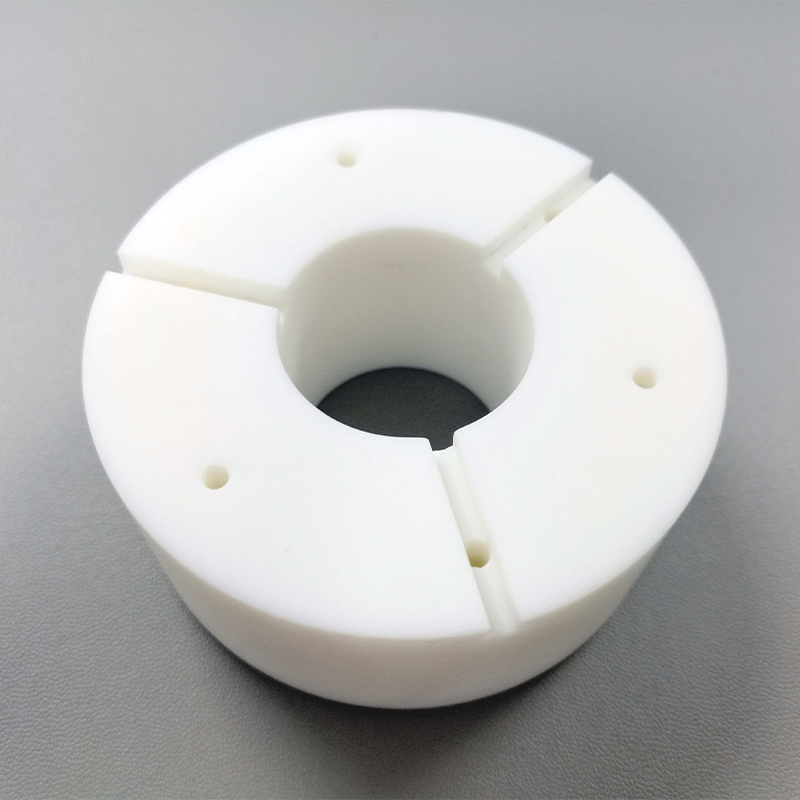

The most outstanding feature of machinable ceramics lies in its machinability, which can meet high-precision technical requirements, without making molds, and directly process and shape, which greatly reduces the design and processing cycle. Machinable ceramics can be flexibly applied to various structural ceramic parts that require complex shapes, high precision requirements, and difficult molding, such as various ceramic thin-walled, ceramic threads, and so on.

Our Machinable Glass Ceramic Services:

Great Ceramic is an expert in the production of technical ceramics. Since 2013, we have participated in and provided more than 3,000 types of precision ceramic products to hundreds of companies.

We can provide you with ceramic processing, ceramic raw materials, ceramic mold forming, surface metallization and other services, and we are committed to providing only products and services that meet or exceed customer quality requirements.

Machining

Materials

Why Use Our Machinable Glass Ceramics?

Because the price of Macor ceramics is relatively expensive, and it is more troublesome for us to obtain them. Therefore, we launched a more favorable price, and the performance of the processable ceramics, as a substitute for Macor.

Machinable Ceramic Products:

Why Use Machinable Glass Ceramics?

-

The most prominent feature of machinable ceramics is that ordinary metal processing tools and equipment can be used for turning, milling, planing, grinding, drilling, sawing and tapping into various parts with complex shapes, and can achieve quite high processing. Accuracy. No special tools and equipment are required. Therefore, it is processed into various structural ceramics with complex structures. Typical applications: insulating pads, heat-insulating pads, insulating supports, and heat-resistant supports on various mechanical equipment.

-

Machinable ceramics is an excellent high-temperature electrical insulation material. Its electrical breakdown strength can reach 40KV/A per millimeter. It can be used in many electrical equipment. Typical application: key parts of lightning rods.

-

The use range of machinable ceramics is -200℃~+800℃. Because the mica crystals in glass-ceramics have certain elasticity and can prevent the extension of micro-cracks, it also has better thermal shock resistance. Its low thermal expansion coefficient ensures the dimensional stability of the workpiece and can be airtightly sealed. Typical applications: welding fixtures, optical glass secondary molding molds, etc.

-

Machinable ceramics have a very low outgassing rate, so they are widely used in support parts in vacuum chambers of various vacuum equipment. Typical applications: vacuum equipment, vacuum coating support for photovoltaic industry.

-

Machinable ceramics have excellent corrosion resistance. It is completely composed of inorganic materials, so it does not age and deform, is very stable to various organic solvents, and has good acid and alkali corrosion resistance. It is more resistant to acid and alkali corrosion than ordinary ceramics and polytetrafluoroethylene. Compared with PTFE, it is more resistant to corrosion, does not age, and has a long service life. Therefore, it is applied to various key parts in the chemical industry. Typical application: introduction of rods and suspenders for crude oil desalination electrodes.

-

Machinable ceramics have excellent electromagnetic properties. Typical application: missile gyroscope coil bobbin

-

Machinable ceramics have excellent self-lubricating properties, and without metal particles, they have self-lubricating properties like graphite. Its specific gravity is 1/3 of ordinary steel, lighter than aluminum, and its water absorption rate is extremely low. Typical application: rotary vane of rotary vacuum pump.

Mechanical Properties

| Properties | Unit | MGC | Macor | HBN |

| Colour | —— | White | White | White |

| Density | g/cm^3 | 2.5~2.6 | 2.52 | 2.0 |

| Hardness | GPa | 4~5 | 2.5 | 0.04 |

| Compressive Strength | MPa | 508 | 345 | 100 |

| Flexural Strength | MPa | 108 | 94 | 30 |

| Fracture Toughness | MPam1/2 | —— | 1.53 | —— |

| Modulus of Elasticity | GPa | 65 | 66.9 | 71 |

| Poissons Ratio | —— | —— | 0.29 | —— |

Thermal Properties

| Properties | Unit | MGC | Macor | HBN |

| Maximum Use Temperature | ℃(No load) | 800 | 800 | 850 |

| Thermal Conductivity @ 20°C | W/(mK) | 1.71 | 1.46 | >30 |

| Thermal Expansion a at 25–200°C | 1 x 10-6/°C | 7.2x 10-7/°C | 9.3 | >1.8 |

| Specific Heat | KJ/kg℃ | —— | 0.79 | 0.81 |

Electrical Properties

| Properties | Unit | MGC | Macor | HBN |

| Dielectric Constant | 1MHz | 6~7 | 6.03 | 4.0 |

| Dielectric Strength | ac-kV/mm | >40 | 45 | 79 |

| Volume Resistivity @ 25°C | Ωcm | >1016 | >1017 | >1013 |

*The values are typical material properties and may vary according to products configuration and manufacturing process. For more details, Please feel free to contact us.

What Can Machinable Ceramics Be Used For?

- Precision coil former;

- High voltage insulator;

- Spacers, cavities and reflectors in laser components;

- Thermal fracture in high temperature processing equipment.;

- Coil support and vacuum feedthrough;

- Aircraft hinges, fixing rings on windows and doors;

- Supports and components;

- Fixing device and reference block in power generation device.

Instructions For Using Machinable Ceramics:

Machinable ceramics are easily affected by halogen acids such as HCl (hydrochloric acid). Tests showed that 2.52 grams (1cc) of the glass ceramic sample was exposed to hydrochloric acid with a pH of 0.1 and lost 100 mg (3.96%) within 24 hours. When exposed to sodium hydroxide with a pH of 13.2, it lost 0.396% in 6 hours. When it exceeds 600°C (in a vacuum), fluorine will precipitate, which is manifested as boron trifluoride or hydrofluoric acid.

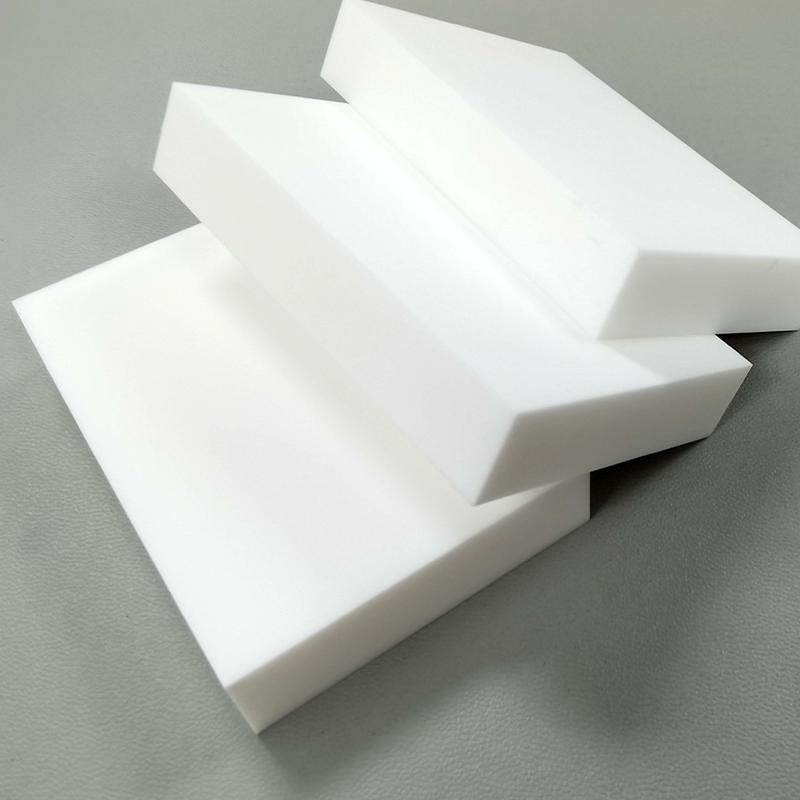

Machinable Ceramic Custom Processing

Great Ceramic is your Machinable Glass Ceramic machining specialist for your precision ceramic prototyping & manufacturing needs; we are always happy to use our many years of advanced ceramics experience to provide advice on materials, design, and application. If you would like to buy Machinable Glass Ceramic plates, rods, tubes or custom machined components, please contact us and one of our experts will be happy to assist you.

Machinable ceramic is a composite material made of fluorophlogopite in a borosilicate glass matrix at a ratio of 45/55, respectively. Its ingredients are as follows:

- 46% silicon dioxide (SiO2)

Machinable ceramic microstructure

- 17% Magnesium Oxide (MgO)

- 16% alumina (Al2O3)

- 10% potassium (K2O)

- 7% boron (B2O3)

- 4% fluorine (F)

Machinable ceramic materials have excellent electrical insulation properties, high mechanical strength, and rapid cold and heat resistance (widely used in welding fixtures, optical glass forming molds, etc.). Its corrosion resistance is also better than ordinary ceramics, and its excellent corrosion resistance makes it used in various chemical equipment. Compared with PTFE, it is more corrosion resistant, does not age, and has a long service life.