- The surface roughness can reach Ra0.02um

- High flexural strength and hardness

- High density – up to 6.0 g/cm^3

- Low thermal conductivity – aprox. 10% of Alumina

- Other characteristics: high electrical insulation, strong corrosion resistance, high biocompatibility

Description

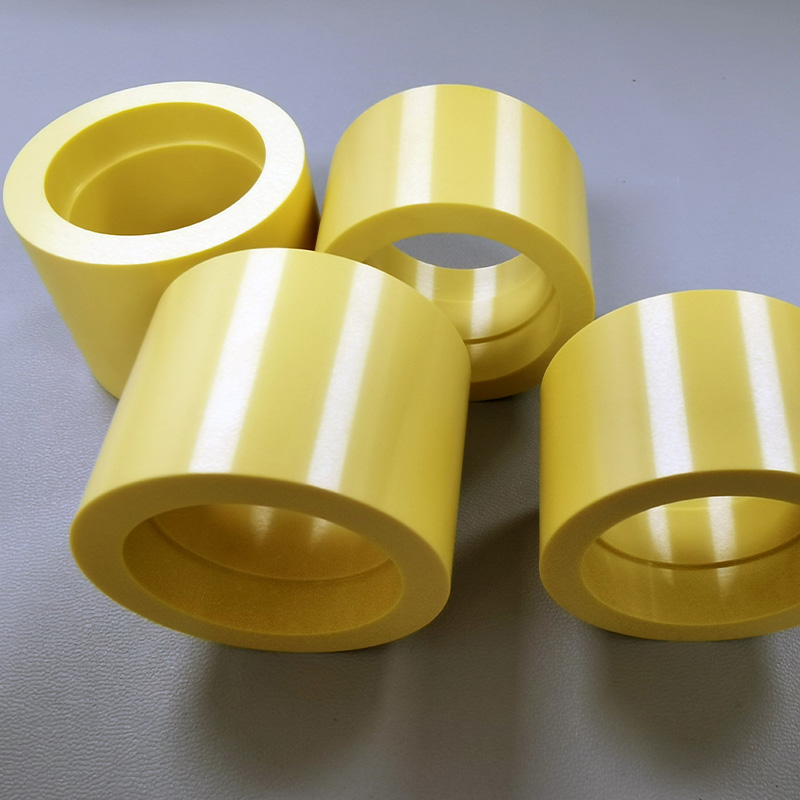

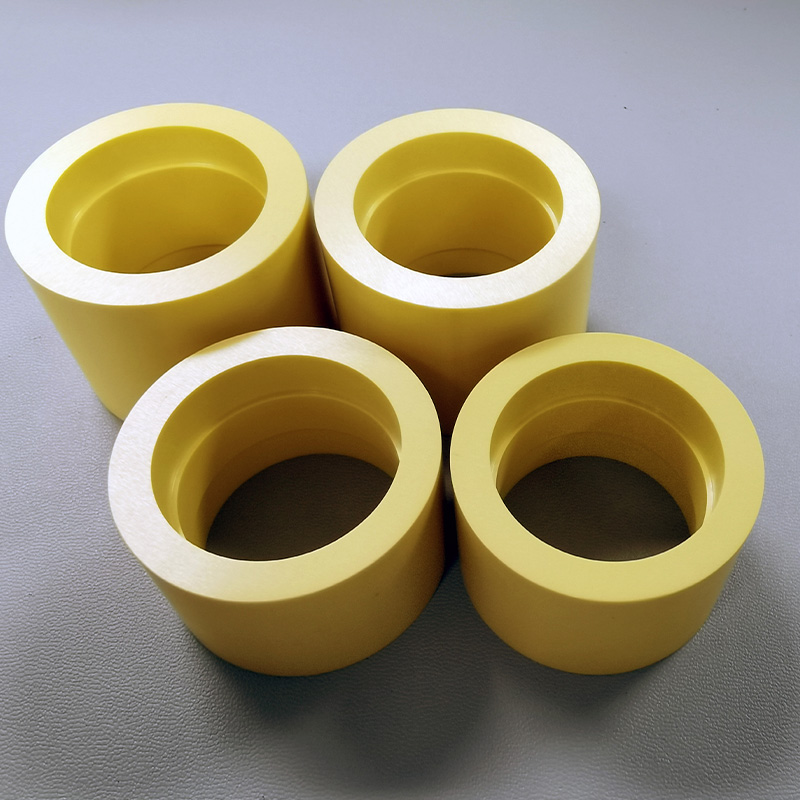

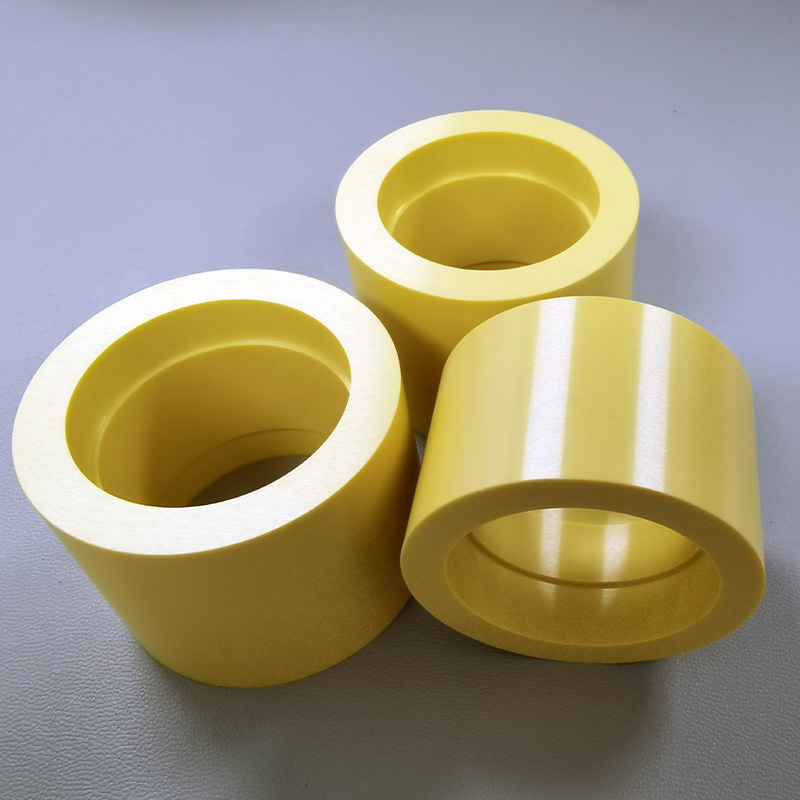

Magnesia Zirconia

Magnesium stabilized zirconia has the highest fracture toughness. It has excellent mechanical properties, including high strength, fracture toughness, wear resistance, good thermal shock resistance and low thermal conductivity. With high wear and corrosion characteristics, magnesium stabilized zirconia is used in valves, pumps and gaskets. Magnesium stabilized zirconia is also the preferred material for chemical processing and petrochemical industry.

While Y-PSZ is well suited for demanding mechanical applications, it may not be suitable for very high temperature applications because it is affected by particle boundary slip; this occurs when long exposure to heat causes the material to transition from a strong tetragonal phase to a weaker monocyte phase. Mg-PSZ has better temperature and moisture resistance because it is not affected by phase migration. The Mg-PASZ maintains its strength even in humid and high-temperature environments where the mechanical properties of Y-PSZ begin to deteriorate.

Feature

Machinability application: it can be processed by common metal processing tools and various equipment, and can achieve high machining accuracy;

Application of insulating property: macor ceramics is a kind of excellent high temperature electrical insulation material, its breakdown strength per millimeter can reach 40KV/A;

Application of heat shock resistance: macor ceramics can be used in the range of – 200 ℃ ~ + 800 ℃. Because mica crystal in glass ceramics has certain elasticity, it can prevent the extension of microcracks, so it has better thermal shock resistance;

Application of corrosion resistance: macor ceramics have excellent corrosion resistance ;

Won’t outgas in vacuum environment;

Toxicological safety.

Structure

China Ceramics Parts has rich experience in milling, grinding and polishing precision (Advanced) ceramics and firing ceramics, which enables us to achieve:

- When the outer diameter accuracy is the best, it can reach ± 0.002 mm, generally ± 0.01 mm;

- When the concentricity accuracy is the best, it can reach 0.003 mm, generally within 0.01 mm;

- The surface roughness of magnesia zirconia ceramic ringcan reach Ra0.02um after polishing, and it is Ra0.4um in general in the state of fine grinding;

- When the roundness is the best, it can reach 0.002mm, and the general accuracy is within 0.01mm;

- Please contact us for other details of the structure.

All tolerances can be improved upon depending on the size, shape & geometry of the precision ceramic part. China Ceramics Parts is dedicated to ensuring we make only the highest quality parts that meet or exceed our customers specifications.

Why Choose Us

China Ceramics Parts has accumulated many years of experience in the pursuit of developing the best precision (Advanced) ceramic parts in the world, and is constantly applying this knowledge every day. In fact, we have been involved in the production of precision ceramics by many customers.

Contact us to find out what we can do for you.

- We can reply to your inquiry within 24 hours (except on Saturdays and Sundays);

- We can provide customized product service for you;

- We can accept the customized service of 1 product.

Packing and Shipping